Equipment for asphalt mix production is more sophisticated than ever, as users are becoming more and more interested in the new technological benefits that these machines offer.Both brands and manufacturers are turning their attention to

high-productivity, low-consumption equipment that meets the highest environmental and emission standards and, in addition, offers options for recycling used asphalt with increasing yields.In this context, Asphalt Mixing Plant manufacturers and brands are developing new technological solutions to meet the needs of users around the world, each geographic and climatic area having their own operating conditions.

Asphalt concrete is a composite material that consists of a mixture of construction aggregate (mineral) bound together with a form of petroleum called asphalt.

The manufacture of asphalt concrete involves heating the asphalt, due to its highly viscous nature, for mixing it with the aggregates. All this process takes place at the Asphalt Mixing Plant.

What is an Asphalt Mixing Plant

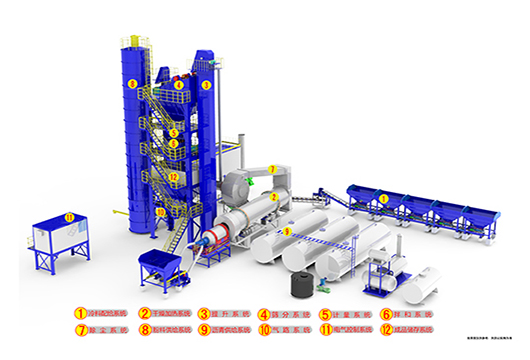

Asphalt Mixing Plant is facilities that are designed and engineered to manufacture asphalt concrete.And we have to admit that an Asphalt Mixing Plant is quite a piece of equipment. Just imagine that from a mixture of asphalt with aggregate and, sometimes, additives added to improve the properties of the final product, results in the asphalt concrete. And this material is used to surface the vast majority of roads.

Main types of Asphalt Mixing Plant

To produce asphalt at an Asphalt Mixing Plant, carefully measured quantities of the raw material are heated to a standard temperature for the asphalt to be formed. Depending on site necessities, the process of making asphalt can be needed continuously or in batches. For this reason, there also are two types of Asphalt Mixing Plant.

·Drum plants used to prepare the asphalt through a continuous process, for continuously production and storage in heated silos for several days. One of the advantages is that is a continuous process that manufactures at a high rate a homogenous mixture.

·Batch plants used for production in small accurate batches, as needed on work sites. One advantage of using a batch plant is that, if necessary, is easy to switch between different mix recipes, due to intermittent production.

Also, if we refer to the mobility required for the installation, we can identify several types of asphalt stations.Stationary asphalt stations that are easily transported from the factory to the site where are mounted on a concrete platform on site.Ultra-mobile asphalt stations designed to produce asphalt directly at the desired casting site Modular asphalt stations which offer the advantage of being easy to relocate, being designed from modules of the right size to be easily transported.

How an Asphalt Mixing Plant work

The process of asphalt( proceso de asfalto ) making consists of:

Placing the aggregates appropriate bins

·Transferring the aggregates to the drying drum by means of a conveyor.

·Efficiently drying the aggregates in a drum dryer.

·Transferring the aggregates vibratory screen to separate them by size.

·The desired type of aggregates is allowed to enter the mixing unit of the asphalt plant.

·Bitumen comes pre-weighed from a heated storage tank.

·The aggregates are mixed with the liquid bitumen in established proportions.

·Hot mix asphalt is ready and is dropped into a truck or hot storage silo.

Noteworthy, also the characteristics of the components have a great impact on the quality of the asphalt mixture.

Areas that Asphalt Mixing Plant are used

We all walk daily on asphalt. Almost all the footpaths and cycle paths, sport and play areas, streets or highways and motorways, parking areas(

áreas de estacionamiento para máquina AIMIX), highways, and motorways are paved with asphalt concrete.

Usually, asphalt is used for paving (asphalting) roads or strengthening the foundations of large buildings. Therefore, the domains that use Asphalt Mixing Plant are constructions and road constructions

In a world where people are becoming more aware of the impact that any action has on the environment, asphalt recycling is a solution that many brands and manufacturers are using. The flexibility and natural component of the asphalt make this material virtually removed, its separate components, and then reused almost indefinitely. For road construction and maintenance is perfect, since recyclable material is always available.

Choose the proper Asphalt Mixing Plant for your projects. When looking to buy an Asphalt Mixing Plant, apart from style, size, brands, and manufacturers, there are other things you need to take into account. Before you decide to buy a particular Asphalt Mixing Plant it is important to check all asphalt plant parts. Make sure that at least it meets your requirement, or even exceeds. The equipment should be easy to transport and maintain.

Depending on the specifics of the works to be executed, it also takes account of the fact that Asphalt Mixing Plant brands and manufacturers have complied with new market demands and trends and have created equipment that can use up to 90% or 100% recycled material to create new asphalt. This can come in handy in certain situations.

Where to buy cheap and quality equipment

There no easy task to buy a cheap and quality Asphalt Mixing Plant. First of all because cheap and quality do not work well together. But this doesn’t mean that it isn’t possible. There are many offers, from many brands and manufacturers. Look carefully and analyze the Asphalt Mixing Plant from all points of view, before deciding which one to buy.

Also, there is always a possibility to find an already used one that may fit perfectly with your necessities and budget. Still, keep in mind that if you buy from someone other than brands or manufacturers a used Asphalt Mixing Plant it will, on the short term, save money but on the long term, it can become an expensive problem.

Things to take into consideration before deciding to buy an Asphalt Mixing Plant

Consider if what you need is a portable or a stationary plant Decide if you need a counterflow or parallel flow plant Analyze the market to determine the tonnage will be needed daily. Look for brands and manufacturers that offer guidance and support in choosing the best system

A type of AIMIX asphalt: aimixgrupo.com/planta-de-asfalto-movil/