Running a profitable operation requires smart tools. A crusher machine is one such tool. It processes raw materials on your site. This ability boosts productivity significantly. It also helps control project costs effectively. This article explains how a crushing machine achieves both goals. We will explore different types and their benefits.

How a Crusher Machine Enhances Productivity

A crushing machine automates a key process. It turns large rocks into usable aggregate. This automation saves substantial manual labor. Your team can focus on other important tasks. The machine also works faster than traditional methods. It produces more material in less time. This increased output keeps your project on schedule. Furthermore, it ensures consistent material quality. You get uniform aggregate size every time. This consistency improves the quality of your final product.

Key Ways to Reduce Operational Costs

On-site crushing cuts several major expenses. First, it eliminates material transport costs. You no longer need to haul raw stone to a plant. You also avoid hauling processed aggregate back. This saves on truck rental, fuel, and driver time. Second, it reduces material purchase costs. You can use on-site rock or recycled concrete. This turns waste into a valuable resource. Third, it lowers disposal fees for demolition debris. You crush and reuse rubble instead of dumping it.

Understanding Different Crusher Types

Several crusher types exist for different needs. Each offers unique advantages for specific tasks.

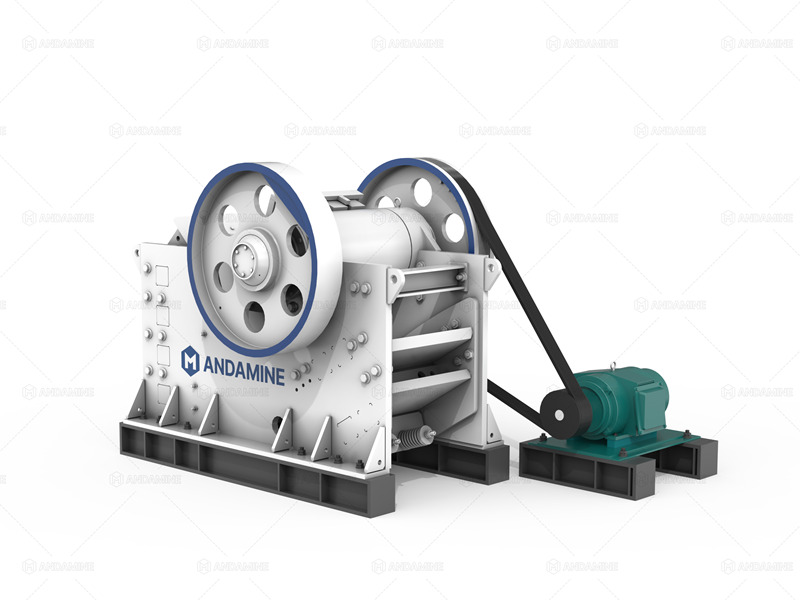

A jaw crusher is a strong primary crusher. It handles the first crushing stage. It breaks down very large and hard materials. This includes granite, basalt, and reinforced concrete.

A cone crusher is often a secondary crusher. It takes material from the jaw crusher. It crushes it further into a finer aggregate. It produces a well-shaped, uniform product. This is ideal for asphalt and concrete production.

Impact crushers are very versatile machines. They can handle primary or secondary crushing. They use impact force to break material. They excel at processing softer rocks and recycling materials.

Choosing the Right Machine for Your Project

Selecting the correct crushing machine is crucial. Consider your primary material type first. Is it hard quarry rock or demolition concrete? Next, think about your desired final product. Do you need large base rock or fine aggregate? Also, evaluate your required production volume. A higher volume needs a larger, more powerful machine. Finally, consider mobility. Do you need a fixed plant or a mobile unit? Answering these questions guides your choice.

Real-World Applications and Benefits

Many industries use crushers to improve efficiency. Quarry operators use them to process extracted rock. Construction teams crush on-site stone for base layers. Demolition contractors recycle concrete and asphalt rubble. Mining operations use them to process ore. In each case, the crusher boosts productivity. It also delivers direct cost savings by using local resources.

Getting Started with Your Crusher

Implementing a crushing strategy is straightforward. First, assess your material and output needs. Then, research different models and manufacturers. Look for a machine that matches your specific requirements. Consider a mobile jaw crusher for primary crushing. A cone crusher is excellent for finishing. Impact crushers are great for recycling. Reputable dealers can provide valuable advice and demos.

Conclusion: A Smart Investment for Your Business

A crushing machine is a practical productivity tool. It increases your output capacity dramatically. It also significantly reduces your material costs. Whether you choose a jaw crusher, cone crusher, or impact crusher, the right machine delivers real value. It helps you complete projects faster and under budget. This investment supports long-term business growth and stability.