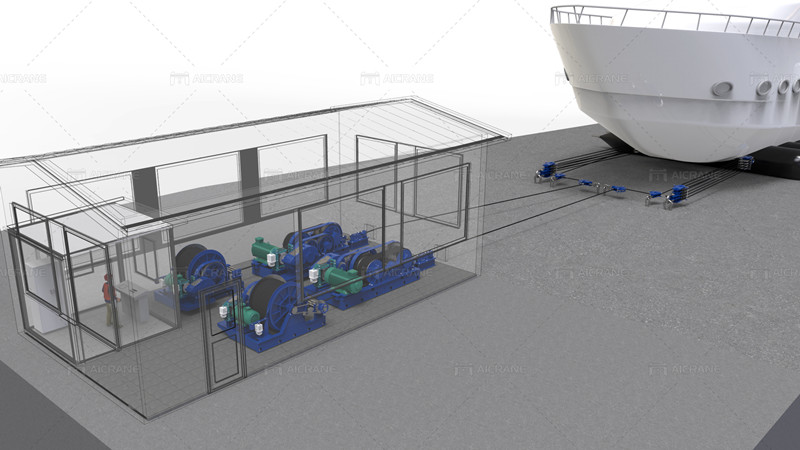

Maintaining a slipway winch accessory is essential for ensuring its reliable performance, safety, and longevity. Slipway winches are used in marine environments for hauling boats, ships, or other watercraft onto slipways or dry docks for maintenance, repairs, or storage. Proper maintenance of the winch and its accessories is critical to prevent equipment failures, accidents, and downtime. Below is a comprehensive guide on how to maintain a slipway winch accessory effectively:

Regular Inspections

Conduct regular visual inspections of the slipway winch and its accessory components to check for signs of wear, damage, corrosion, or abnormalities. Inspect the winch drum, wire ropes or cables, sheaves, pulleys, bearings, gears, brakes, motors, controls, and safety devices. Look for frayed cables, worn-out brake pads, loose fasteners, leaking seals, or any other issues that may affect winch performance or safety.

Cleanliness and Lubrication

Keep the slipway winch and its accessories clean and free from dirt, debris, saltwater residue, and contaminants that can cause corrosion, abrasion, or mechanical failures. Use mild detergent, water, and a soft brush to clean winch surfaces, wire ropes, pulleys, and other components regularly. Avoid using harsh chemicals or high-pressure washers that could damage seals, bearings, or electrical connections. Apply appropriate lubricants to moving parts, bearings, gears, and cables to reduce friction, wear, and corrosion.

Wire Rope Maintenance

Inspect wire ropes or cables for wear, kinks, broken strands, rust, or signs of fatigue. Replace damaged or worn-out wire ropes promptly to prevent accidents or failures during lifting operations. Clean and lubricate wire ropes regularly to enhance their durability, flexibility, and corrosion resistance. Use proper spooling techniques and tension adjustments to prevent rope slippage, bird caging, or rope jamming on the winch drum.

Brake System Inspection

Check the brake system of the slipway winch for proper functioning, adjustment, and wear. Inspect brake pads, discs, calipers, hydraulic cylinders, and control mechanisms for signs of wear, contamination, or hydraulic leaks. Ensure that the brake system engages and releases smoothly, and that brake force is sufficient to hold and control loads during winching operations. Adjust brake settings or replace worn brake components as needed to maintain braking performance and safety.

Electrical System Maintenance

Inspect the electrical components of the slipway winch, including motors, controllers, wiring, connectors, switches, and sensors. Check for loose connections, damaged cables, overheating, or electrical malfunctions that may affect winch operation. Test electrical circuits, control functions, emergency stop buttons, and safety interlocks to verify proper functionality and compliance with electrical standards. Clean electrical contacts, terminals, and components regularly to prevent corrosion or electrical faults.

Safety Devices and Controls

Verify the functionality of safety devices and controls on the slipway winch, such as limit switches, overload protection, emergency stop buttons, fail-safe systems, and remote control devices. Test safety features during pre-operation checks to ensure they respond correctly and effectively in emergency situations. Train operators and personnel on the proper use of safety devices, emergency procedures, and shutdown protocols for the winch accessory.

Alignment and Tensioning

Check the alignment of sheaves, pulleys, and guides on the slipway winch to ensure smooth cable movement and reduced wear. Adjust sheave positions, cable paths, and tensioning settings to optimize cable tracking, reduce friction, and minimize side loads on the winch drum. Proper alignment and tensioning contribute to efficient winching operations, cable longevity, and reduced maintenance requirements.

Environmental Protection

Protect the slipway winch and its accessories from environmental factors such as saltwater exposure, UV radiation, extreme temperatures, and harsh weather conditions. Apply protective coatings, paints, or corrosion inhibitors to metal surfaces, cables, and components to prevent rust, corrosion, and deterioration. Store winch accessories in covered or sheltered areas when not in use to minimize exposure to the elements and extend their service life.

Training and Operator Competence

Provide comprehensive training and instruction to operators, maintenance personnel, and staff involved in using the slipway winch and its accessories. Educate operators on proper winching techniques, safety procedures, equipment capabilities, load handling practices, and maintenance requirements. Promote a safety culture, encourage regular equipment checks, and empower operators to report any issues or concerns related to marine winch performance or safety.

Documentation and Records

Maintain detailed records, logs, and documentation of slipway winch maintenance activities, inspections, repairs, replacements, and performance data. Keep track of maintenance schedules, service intervals, parts inventory, and equipment history to track maintenance costs, compliance with regulations, and equipment reliability. Use digital or paper-based maintenance logs, work orders, and inspection reports to record observations, findings, and corrective actions taken during maintenance activities. Get more information about maintenance from winch manufacturer.

By following these maintenance practices and protocols, operators and maintenance teams can ensure the reliable performance, safety, and durability of slipway winch accessories. Regular inspections, cleaning, lubrication, brake checks, electrical testing, safety checks, and operator training contribute to effective winch maintenance and safe winching operations in marine environments. Investing in proactive maintenance and safety measures helps maximize equipment uptime, minimize downtime, and protect personnel and assets during slipway operations.