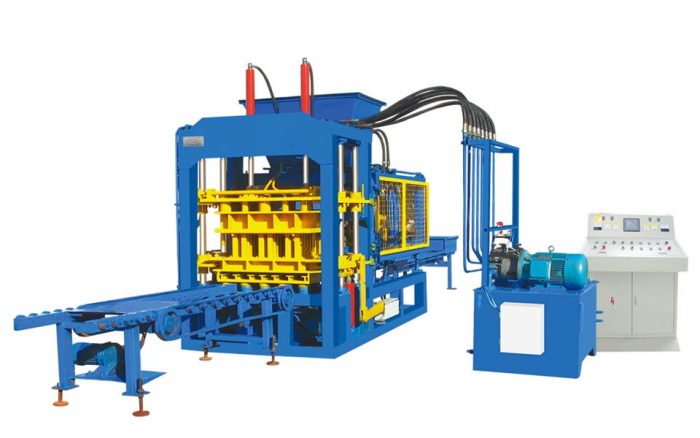

Leading manufacturers of automatic brick making plants have significantly stepped up their game. As such, they are now creating plants that ensure that customers are fully satisfied and they also provide the most reasonable prices. When it comes to buying a high-quality plant, you’re going to need to consider a few things. Our article features some important information about the automatic block making plant.

These plants are typically offered in a semi-automatic or a fully automatic brick making plant. However, the final decision is based on the projects that you plan to undertake as well as the investment that you want to make. These machines are provided to ensure that you receive the perfect degree of automation that you’re searching for and they are also produced to follow the highest industry standards.

Different capacities

Additionally, machines come in various capacities as well as with a series of different molds that can be used for different types of jobs. In the case of semi-automatic automation, this is more suited for beginners who lack some experience and would like to be a producer that involves more labor. In the sense of automatic automation, this is well suited for experienced customers who can function with less labor. The last type is the fully automatic option which can be used for those who prefer to have maybe one or two people on their team.

When it comes to the overall production capacity, you’re going to be able to produce between 4000 and 10000 with each 8-hour session. However, if you’re interested in continuous operations, these plants can also work for a full 24 hours and you’re going to produce three times the amount of bricks. So, if you’re interested, in maximizing on the construction industry, you can easily contact a leading brick manufacturer of automatic machine with all of your questions.

High performance

Automatic brick making plants also ensure the highest performance and they are also able to create beautiful paving blocks, insulated bricks, curbstones, hollow blocks, and even chimney blocks. These machines are also properly suited and fully integrated with the leading and latest technology in the markets. Maintenance operations are also carried out easily since various parts can be easily sourced around the globe.

The following are a list of some important features that you’re not always going to find with inferior machines.

*Quality – one of the biggest and most important things when buying a block making plant is the quality. These machines were designed to be of the highest standard and they were built with the best materials found.

*Service – leading manufacturers ensure that they offer prompt service as well as highly trained technicians to fully support your needs. With the evolution of technology, they’re also offering full online support.

*Replacement Parts – manufacturers are also going to be able to provide any part that you may need in a short space of time.

As we conclude, we have just looked at what you will need to consider before buying an automatic blocks machine. So, be sure to perform enough research before you select a supplier. It is also a great idea to ensure that they provide fast and accurate after service solutions to suit your needs.